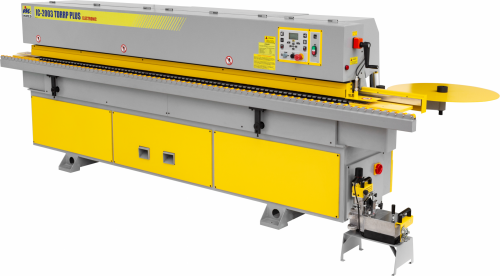

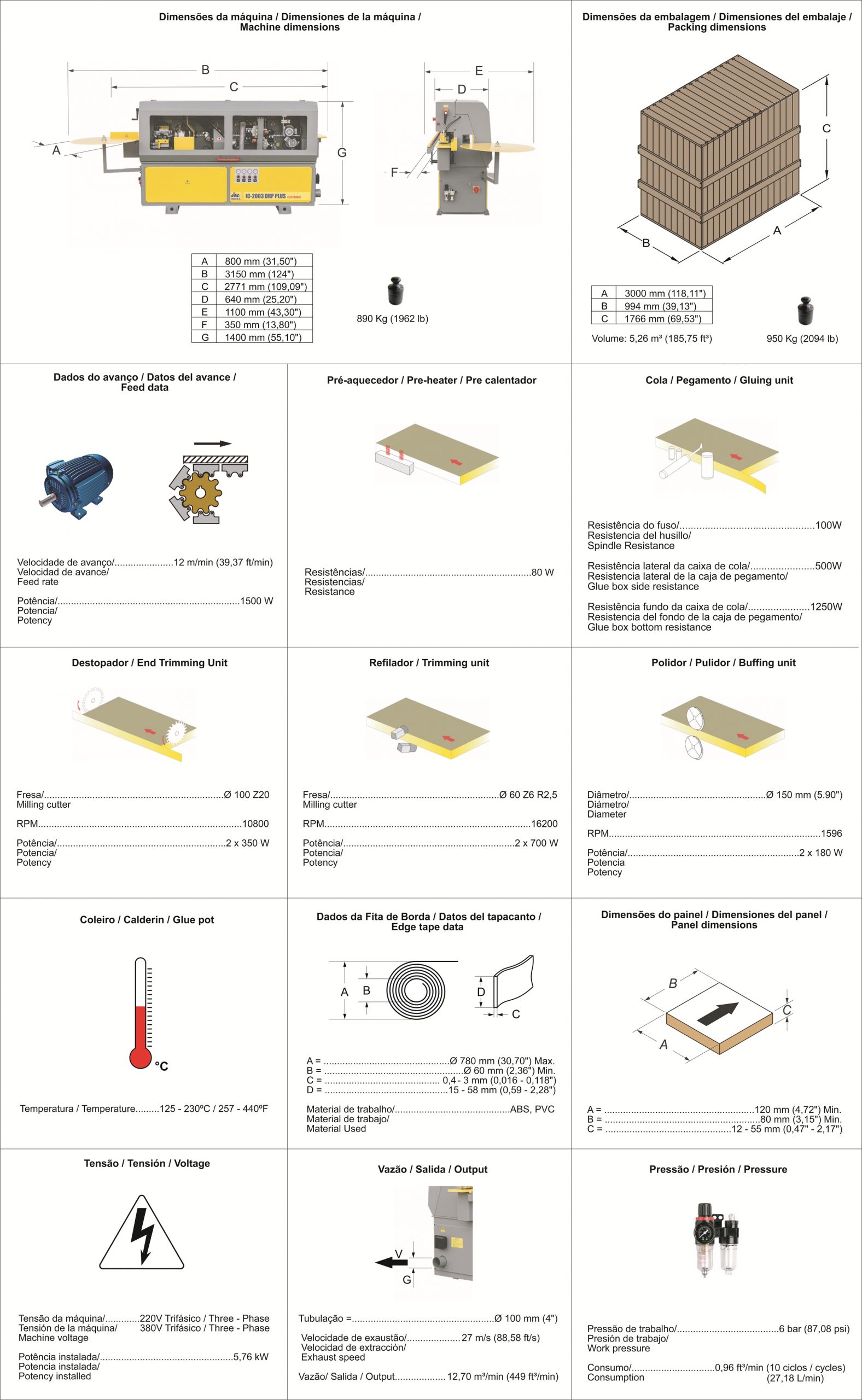

Edge Banding IC-2003 DRP Plus Electronic

The IC-2003 DRP Plus Electronic Edge Gluing Machine has the functions: pre-heater, glue, detopper, trimmer and polisher. It also has the “Stand By” system, which automatically lowers the temperature.

COLADEIRA DE BORDA IC-2003 DRP PLUS ELECTRONIC:

You asked and Inmes Fez! A novelty in the furniture market, ensuring More Flexibility, Economy, Productivity and Quality you already know!

MORE FLEXIBILITY:

The manufacture of bespoke furniture requires professional and increasingly flexible equipment. Access to the most varied MDF standards has required versatile machines, that's why Inmes developed the IC-2003 DRP Plus Electronic, which has a fast collar change system, providing you, carpenter friend, flexibility every day. day.

MORE SAVINGS:

With a modern panel, the IC-2003 DRP Plus Electronic goes into standby mode, automatically lowering the glue temperature after 15 minutes without being used, avoiding glue burning and energy consumption.

MORE PRODUCTIVITY:

The new IC-2003 DRP Plus Electronic is faster, now you can glue with a speed of 12 m/min thus increasing the productivity of your joinery.

HIGHEST BENEFIT COST:

IC-2003 DRP Plus Electronic, glues, tows, trims and skips. With a modern and intelligent panel, in addition to providing energy savings, it increases the useful life of the components.

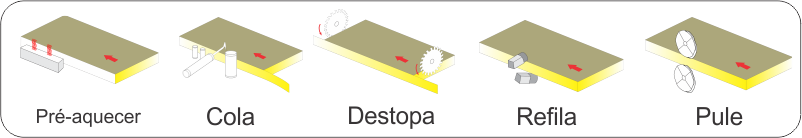

PRE-HEATER

The pre-heater heats the piece, so that when it comes into contact with the adhesive, it does not cool it, increasing the quality of the bond.

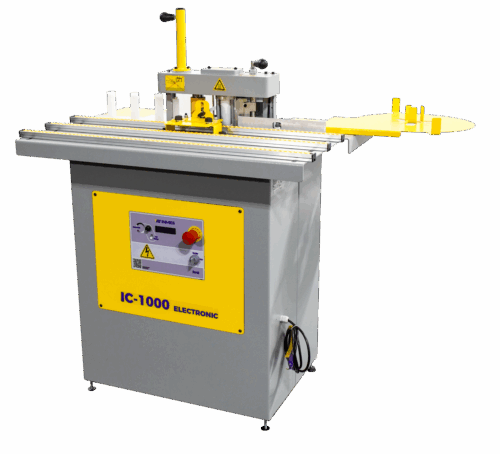

PARTS OF ENTRY CONTROL

IC-2003 DRP Plus Electronic is equipped with a mechanical and luminous parts input controller, to avoid accidental shock of the trigger with these.

THE EXCHANGE collared

On the IC-2003 DRP Plus Electronic Edge Collar, it is possible to change the collar in a practical and fast way, ensuring greater productivity in the use of various types of adhesives. (Second collar optional)

rolos PRESSORES

Pneumatically actuated for force regulation, the pressure rollers ensure uniform pressure on the edge tape, ensuring perfect bonding.

DESTOPADOR

The detopador set is equipped with 2 saws driven by 2 engines of 0.5 CV each, working at 12,000 rpm, providing a superior finish.

REFILADOR

With a practical adjustment system, the IC-2003 DRP Plus Electronic refiller set is equipped with 2 cutters driven by 2 1.0 CV motors each, working at 12,000 rpm, providing a superior finish.

POLIDOR

The polishing set provides a fine finish, removing the remains of adhesive and polishing the piece / tape set.

RIBBON EXCHANGE

On the IC-2003 DRP Plus Electronic gluer, it is very easy to change the tape thickness. You can use a piece of tape of the desired thickness as a reference for the adjustment.

ADJUSTMENT PANEL

The force on the tape press rollers as well as the cutting force of the rippers can be easily regulated.

ADJUSTABLE THICKNESS

Adjusting the gluing height is very simple. Just measure the thickness of the panel to be glued and use the adjustment lever to find the corresponding measure. This process takes just a few seconds.

PANEL

With an easy access and operation panel, it is possible to turn the groups on and off, adjust the size of the leftover tape, adjust the temperature of the pre-heater and the glue, access the maintenance screen and control the working time.

Note: Adhesive is applied to the part. This equipment is designed for straight parts. To glue other materials, consult the factory. For different types of materials different types of adhesives are required, consult the adhesive manufacturer.

RECOMMENDED EXHAUST FAN: EF-300 T2.

* Inmes reserves the right to make changes to its products without prior notice.

** The photos on this website are illustrative.

English

English Português do Brasil

Português do Brasil Español

Español