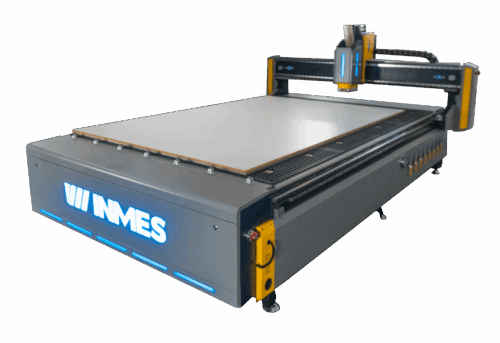

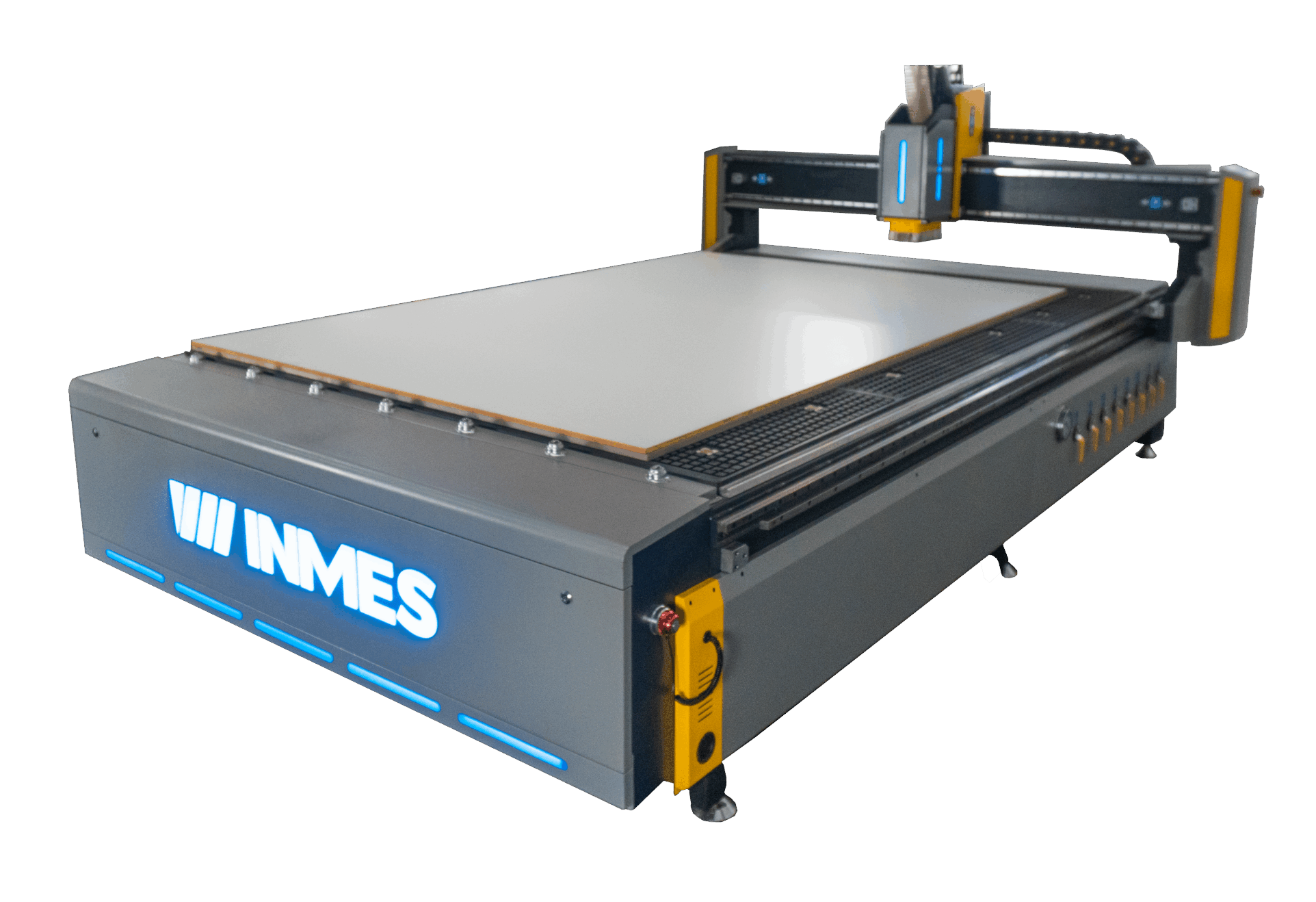

Router IR-25K

The IR-25K Router is a robust and versatile machining center, developed to raise the standard of productivity and quality in your projects. More than a machine, it is a complete solution, which combines power, precision and cutting-edge technology to transform your production process. Ideal for woodworks and industries seeking efficiency, the IR-25K Router guarantees impeccable finishing, agile and reliable operation, as well as offering features that make everyday life easier and increase the performance of your production.

Designed to serve carpentry and furniture industries that seek agility, quality of finishing and greater production efficiency, the Router IR-25K is the ideal choice for those who do not compromise on excellence in their projects.

✅ Sturdy and durable structure

✅ Precise machining of different materials

✅ Easy operation and maintenance

More than a machine, an investment in the productivity of your business.

Robustness and Quality

A robust Machining Center, with 3 high-performance axes, developed for those who demand reliability and consistent results.

Power and Performance

Spindle with 9 hp / 18000RPM power, guarantees precise and efficient cuts, even in continuous operations.

Precision and Movement

With step-servo drive and mechanical rack and pinion transmission on the X and Y axes, and ball screw on the Z axis, the Router IR-25K offers precision and smoothness in each operation.

Technology and Usability

With an intuitive panel, PROBE sensor for measuring tool height and automatic lubrication system, operation becomes simple and productive. Furthermore, it does not require a pneumatic connection, just electrical power and exhaust.

PROBE

PROBE is a device developed to speed up and guarantee precision in the tool changing process. Its main function is to quickly zero and calibrate the tool, eliminating measurement errors and reducing setup time.

SPHERES

Balls are essential components in the MDF sheet feeding process. Installed on the machine structure, they reduce friction between the sheet surface and the machine, allowing lighter, more precise and safer movement during handling.

VACUUM TABLE

The vacuum table is divided into 8 independent sectors, with manual activation, allowing suction to be directed only to the region used in machining. This system guarantees better fixation of the sheet, optimizes vacuum consumption and increases the efficiency of the production process.

SPINDLE

Spindle de 9cv / 18000RPM

PANEL

Intuitive control panel with Handle / MPG

LUBRICATION

Automatic lubrication system

See some more features of the IR-25K Router

*Axle 9 hp / 18000RPM

*Cutting speed from 5,000 mm/min to 11,000 mm/min

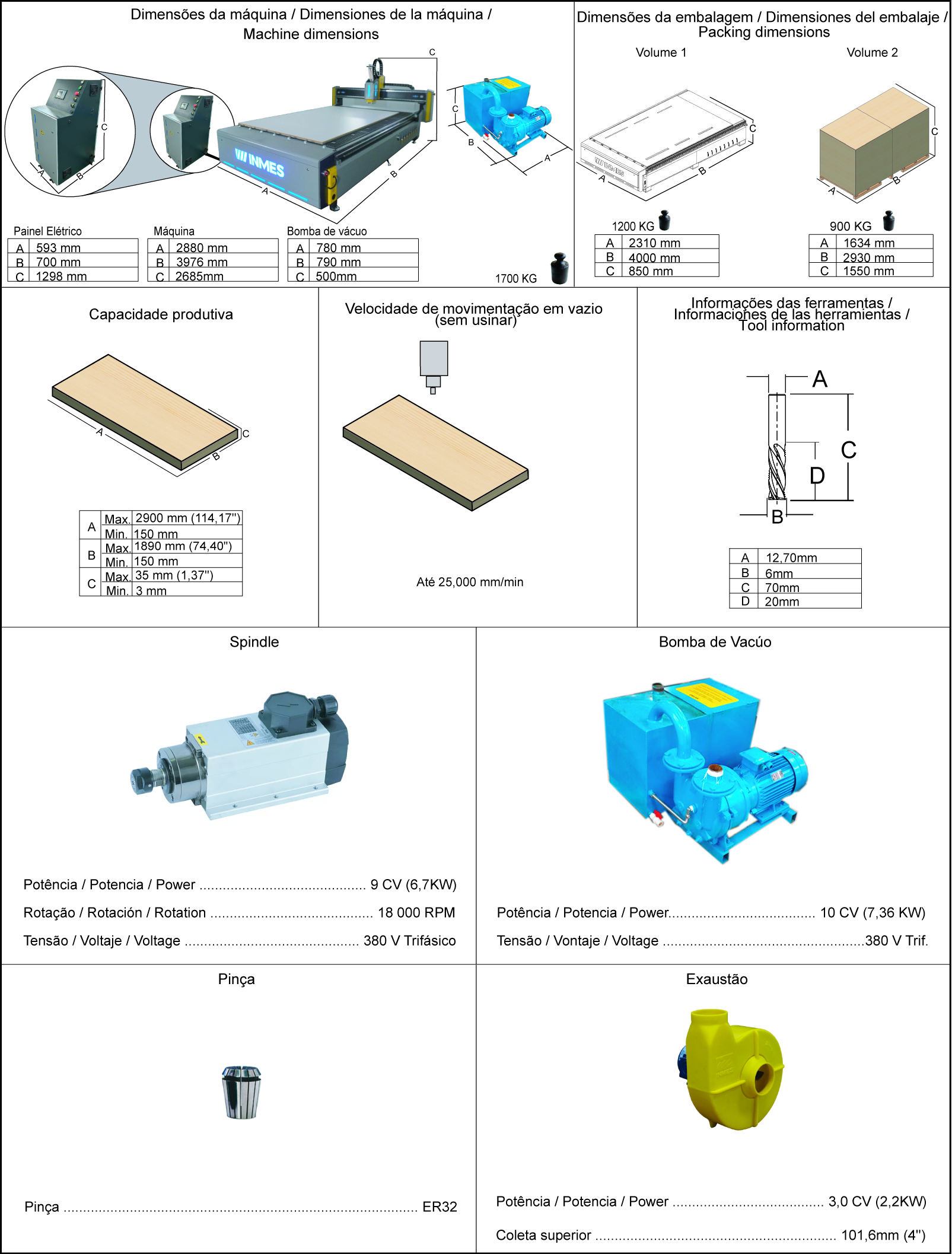

*Machine dimensions 2,880 x 3,976 x 2,685mm

*Cone and Caliper ISO 30 ER32

*Hand Tool Change

*Automatic Lubrication

*Vacuum/T-SLOT Attachment Type

*Exhaust fan recommended EF-300 T2

*Weight 1,700 kg

Technical Specification

English

English Português do Brasil

Português do Brasil Español

Español