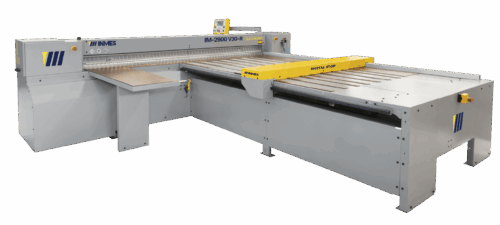

Beam Saw IM-2900 V30 Electronic

The IM-2900 V30 Electronic beam saw has a digital stop that automatically positions at the operator's command, optimizing your productivity to the maximum.

BEAM SAW IM-2900 V30 ELECTRONIC WITH “DIGITAL STOP”, “AUTO POSITION”, “ECO MOTION” AND “AUTO SPEED”: A BIG SUCCESS IN YOUR FURNITURE FACTORY.

More precision, productivity and quality. A modern and affordable machine for those who do not give up an advantageous cost-benefit.

In addition to the already established systems, "Auto Position", "Auto Speed" and "Eco Motion", the IM-2900 V30 Electronic beam saw is equipped with a modern "Digital stop" system that guarantees the measurement of the part to be cut, with a simple touch on the panel.

More precision.

More precision..png) More Productivity.

More Productivity. _small.png) More speed. More productivity.

More speed. More productivity._small.png) More energy savings.

More energy savings.SAFETY SWITCH

The IM-2900 V30 Electronic beam saw is equipped with a security key on the access door to the saw and marker, allowing the door to be opened only in maintenance mode.

TRANSVERSAL GUIDES

For better cutting, the car of the IM-2900 V30 Electronic beam saw has its structure made of steel, more durable and resistant. Mounted to the machine through linear guides, the car that transports the saw moves up and down with precision, offering more precision to the cut.

LONGITUDINAL GUIDES

The word innovation is taken seriously by the engineers at INMES. The IM-2900 V30 Electronic beam saw is built with and innovative system of cylindrical guides, for the longitudinal displacement. Made of special steel, tempered and rectified, the guides provide more durability to the equipment and much more precision to the cut.

MOTOR

Equipped with a 5.0 HP motor for the saw and scribe, the IM-2900 V30 Electronic combines efficiency with low energy consumption.

DUST EXTRACTION

For a healthier environment and to save space, the IM-2900 V30 Electronic beam saw is built with a slide-type dust extraction system, providing more efficiency and more durability to the equipment (it does not use tubes in the internal area) and has only one extraction point, in the lower part of the machine.

TRANSPARENT FLAP

At INMES, all machines are designed to satisfy several aspects. One of the most important is safety. Therefore, the IM-2900 V30 Electronic is equipped with and exclusive transparent flap which allows the operator to visualize the saw blade during its movement.

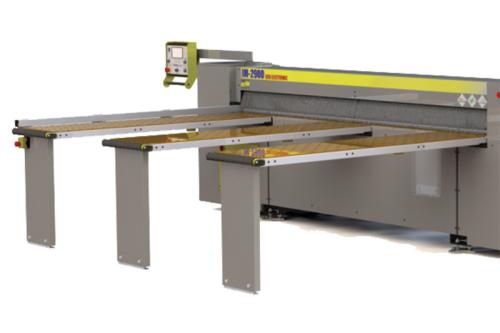

TABLES WITH AUXILIARY ROLLERS

When an artist works on a masterpiece, he strives for perfection. Therefore, INMES concerns about the details. The IM-2900 V30 Electronic has working tables covered with low friction material, resistant to wear. The tables which receive the material to be cut have rollers which help make the movement easier, avoiding damages to the material.

AIR TABLE

Productivity is a constant need in the furniture industry, which is why the IM-2900 V30 Electronic beam saw makes it possible to install a table with an air system, facilitating the movement of the planels. (Optional)

PANEL

Productivity is a key word in the IM-2900 V30 Electronic beam saw, so it is equipped with a dynamic and easily accessible panel. You can turn the machine on and off, start and stop the cut, move the position of the digital stop and even use the USB port to import the cut plans still on the panel display, set up your cut plan and execute.

STOP DIGITAL

Precision and speed are essential to obtain productivity, that's why the IM-2900 V30 Electronic is equipped with a modern Digital Stop system, guaranteeing a fast and precise cut with less manpower.

SECURITY LOCK

Safety is essential, so the IM-2900 V30 Electronic beam saw is equipped with a safety lock next to the digital stop.

ARTICULATED TIP

The articulated tip allows the cutting of one plate or several simultaneously, guaranteeing a perfect square.

SEE MORE SOME FEATURES OF THE IM-2900 V30 ELECTRONIC.

* Quick and precise adjustment of the stops;

* Quick change system for the main and scoring blades;

* Exclusive height and lateral position adjustment system for the scoring blade;

* The machine informs when lubricating is necessary;

* Automatic control of the car position for cutting small pieces;

* Counter of cut pieces, total and partial.

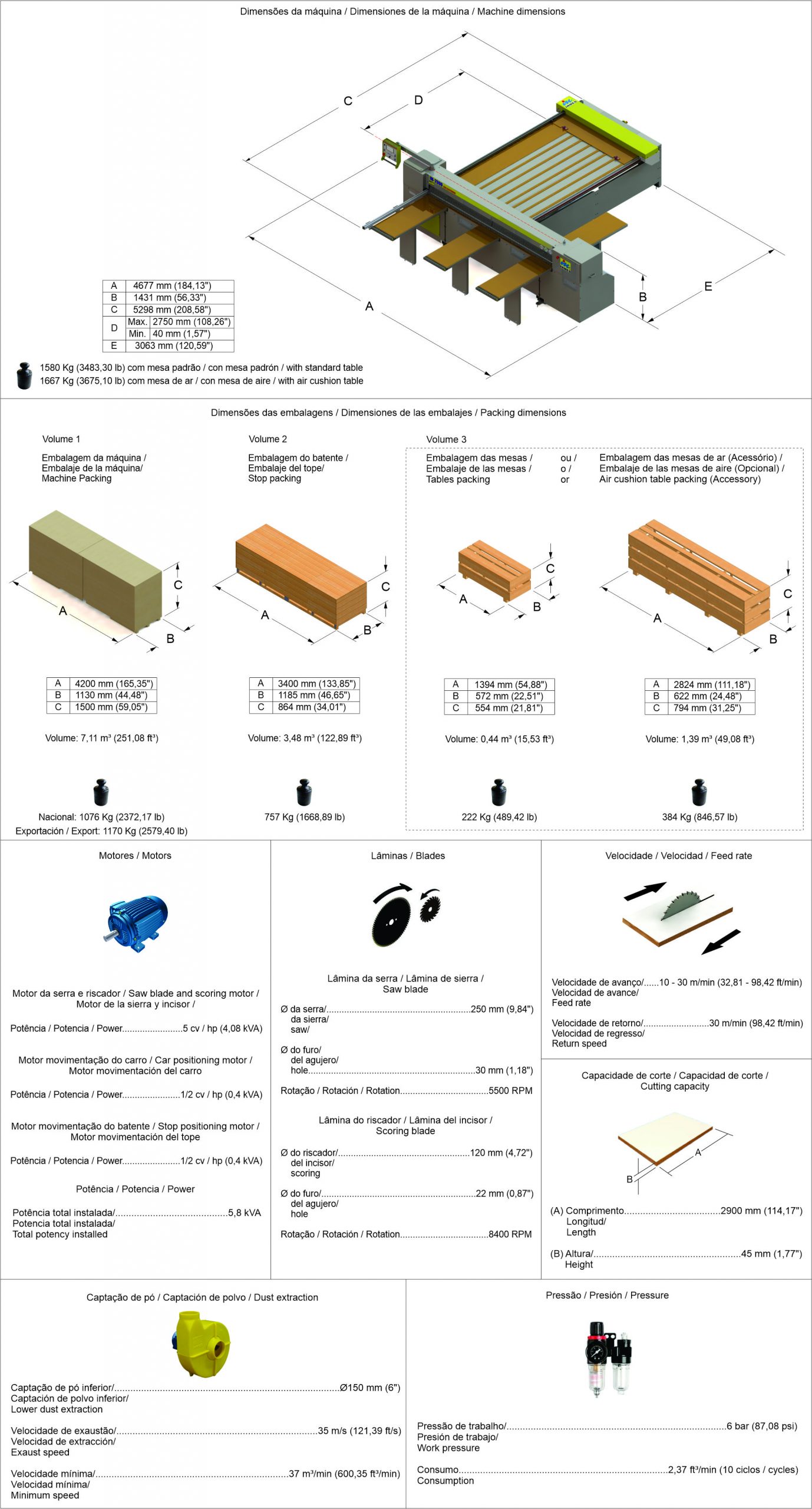

TECHNICAL SPECIFICATIONS:

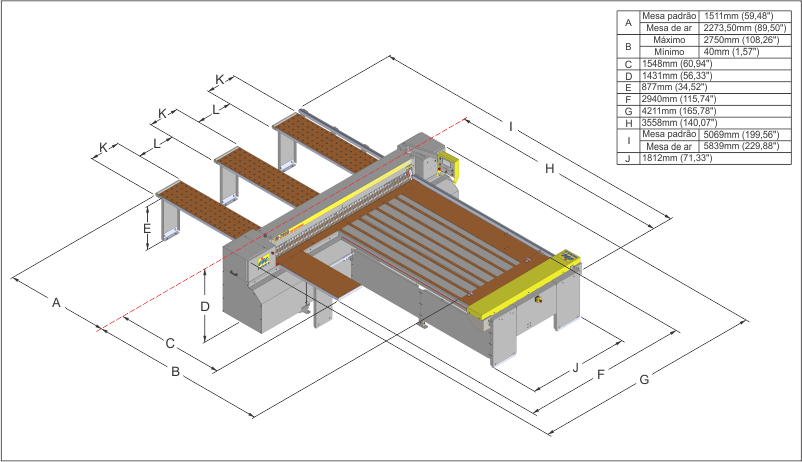

MAIN DIMENSIONS:

** The photos on this website are illustrative.

English

English Português do Brasil

Português do Brasil Español

Español

IM-2900 V30 Automatic disconnector

IM-2900 V30 Automatic disconnector